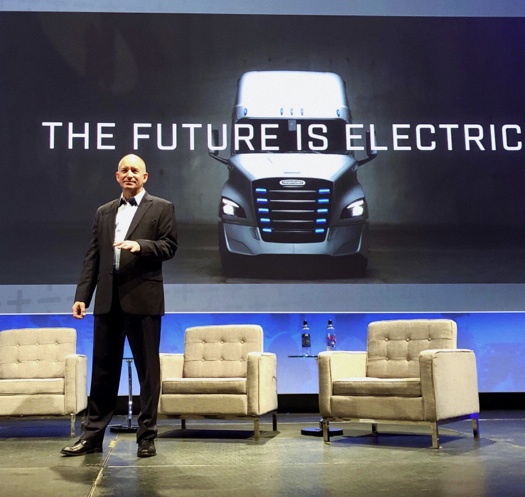

Today I was in Long Beach, California, a region with some of the most challenging air quality issues in North America. I stood in front of the audience at the Advanced Clean Transportation (ACT) Expo proudly knowing that if my team drove our clean diesel, industry-leading Freightliners through the city, the air would be cleaner from our exhaust than the air they intake with the pollution. We will continue to engineer efficiencies across different technologies, but today I was there to confidently share my conviction that the road to emissions-free driving is going to be driven with battery-electric vehicles.

52% of the trucks operated by the Top 100 fleets in America carry the Freightliner nameplate on the nose of the hood. That is three-quarters of a million trucks under the ownership of CEOs like me. These are my largest customers. And, lately, these CEOs have a few questions for me, including: when will battery-electric trucks be a viable choice for my fleet?

We make real reliable trucks and buses in the real world, running them in extreme conditions, testing with our customers as part of our co-creation process with them. 18 months after I commissioned an internal swarm team to deliver an electric solution, we will soon have nearly 50 battery-electric trucks and buses running every day across the country. We are delivering real freight, picked up at real shipping docks, picked up at real ports, and delivered to real receiving docks. These are tried and tested, reliable, real trucks, with a strong manufacturing footprint, real customers, and a field service network coast-to-coast, border-to-border. They are powered by Daimler.

Exciting stuff, yes. But, it is early and some challenges are ahead of us. I shared the path to get there.

To start, we need a common charging interface. To get there, we partnered with other entrepreneurs, OEMs and utilities by leading the CharIN Task force to establish a global standard.

Battery packs are still too expensive, large, and heavy. Financial incentives and government-industry partnerships are needed to scale up. Partners at the South Coast Air Quality Management District, the EPA and the Ports of Los Angeles and Long Beach have all used their resources to help our customers deploy trucks on the streets of Los Angeles and Orange County. The cost of batteries, needs to be cut in half. The weight of batteries must be reduced and the size must be more energy-dense.

Additionally, we will continue to use our own money and talent to help bring the costs down to where there is a viable business case. As we hold true to our commitments, customers have to have the chance to lower their real cost of ownership. I believe in the power of scale. We need to scale up, sell more vehicles, and continue to bolster the business case with financial incentives so we can get more truck on the road to test.

At Daimler, testing and reliability are core values and the DNA of our brands. We will put more and more vehicles into customers’ hands so we can relentlessly test and validate the electric vehicle performance. Since we delivered our first medium-duty electric Freightliner eM2 truck this past December, it has been working as part of our customer’s fleet on the roads throughout the greater Los Angeles metro-area.

In addition, we have the advantage of being powered by Daimler globally which means we will have nearly 200 trusted, reliable electric trucks and buses running every day around the globe. We have thousands of engineers around the world perfecting electric vehicles. We’re uniquely positioned to be able to leverage this wealth of knowledge and capability.

We are testing with our customers, day-in and day-out with real trucks for the real world, running them into the ground, learning and finding solutions in a collaborative co-creation process. No other OEM can duplicate what we’re doing.

By the time we are ready for mass production, we will have millions of miles of road experience.

We will build electric school buses in the Carolinas – powered by Proterra and assembled by Thomas Built Buses. Our EPA and California Air Resources Board (CARB) applications for an electric school bus have been submitted, and we look forward to taking orders (and building buses!) the moment we receive the go-ahead.

Because the future is electric, today I announced that we will manufacture Freightliner battery-electric vehicles in our backyard in the Silicon Forest of Portland, Oregon. Our plant next to our North American headquarters in Portland is being renovated to produce our battery-electric Freightliner trucks and it will run on 100% renewable energy at the start of production and adhere to the zero waste to landfill protocols.

Customers know and expect reliability, safety, and dependability. These values are core to our 120-year-old heritage as a truck manufacturer. When we deliver battery-electric vehicles to the marketplace, the tradition of these values will be evident. We are not compromising, and we are not launching prototypes into outer space. We deliver real, reliable, tried and tested trucks for the real world.

For us, we are committed. This is our future. I will continue, and hope my industry colleagues continue to push electric solutions faster than the speed of change. As I encourage my team, I also encourage all of the industry to push their teams to continue to be agile as we learn, test, grow, embrace, collaborate and lead the charge forward. This is the beginning of the post-internal combustion engine era for commercial vehicles. I am proud and honored to help our generation pave the road forward.

The recording of the live stream is available on the ACT Expo Facebook page at https://www.facebook.com/ACTExpo

If you keep an eye out for new trucks—anywhere on the highways of North America—you’re bound to have noticed the sharp, distinctive lines of the new Cascadia, launched by Freightliner in 2017, but there’s a lot more to this truck than a killer chassis design. It’s packed to the gills with engineering innovation—the hallmark of Daimler Trucks North America—and loaded with cutting-edge breakthroughs in safety, fuel efficiency and connectivity. Today, we’re thrilled to announce a series of model-year 2020 enhancements to the new Cascadia, making it even safer, more efficient and better connected. Some of these innovations have never been seen in a class-8, on-highway truck, and others are more subtle, but together their impact is palpable.

Read MoreNew opportunities and accelerated advancements in technology are changing businesses around the world in a drastic and dynamic manner.

The commercial vehicle manufacturing industry is no exception and developments such as autonomous driving, additive manufacturing, and artificial intelligence are integrating into the value chain in an effective and future-oriented way.

Daimler Trucks North America (DTNA), in partnership with Ginkgo Management Consulting, has developed a comprehensive IT strategy to drive their transformation towards the Intelligent Company.

Read More